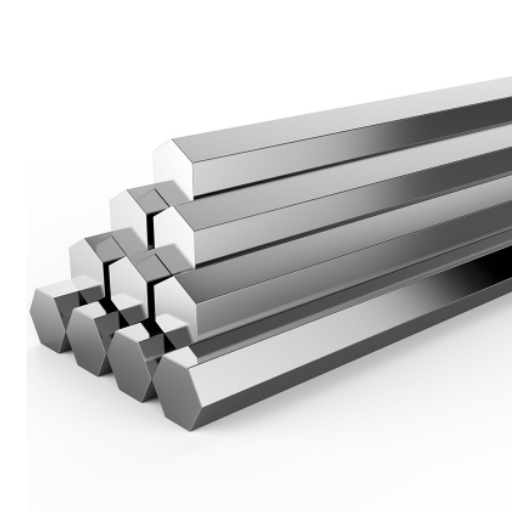

Stainless steel hexagonal bars are essential in many technologies and industry applications as they are highly versatile. This text will focus on these bars’ construction, manufacturing, and engineering uses. Their tensile strength and high corrosion resistance, combined with general resistance to many mechanical and chemical factors, allow them to be used in strong constructions. Moreover, the readers will be able to learn about the different kinds of stainless steel and their properties, thus knowing which one will suit their requirements the best. Using examples of specific applications and their performance parameters, the post outlines the key reasons why stainless steel hexagonal bars are widely used today and how they are incorporated into engineering solutions.

What Makes Stainless Steel Hex Bars Unique?

When speaking of stainless steel hex bars, what comes to mind is their unique character shape and various metal properties that make these bars beneficial for industrial use. First, using stainless steel alloys with hexagonal cross sections creates a geometry that enhances strength and torque resistance, making them suitable for light machine parts and fastening operations. This is coupled with the fact that stainless steel has excellent corrosion resistance, thus enhancing the working life of the components, especially in applications where it is covered with moisture and chemical substances or is placed in extreme temperatures. Different types, for example, 304 and 316 stainless steel, have respective features: 304 has excellent formability and weldability, whereas 316 is better suited for marine applications as it has improved corrosion resistance due to molybdenum. All these and the ability to withstand high stresses show how versatile and significant stainless steel hex bars are in today’s modern-day engineering practices.https://ssalloy-steel.com/stainless-steel-rod/

Understanding Hex Shape and Its Applications

I understood that the hexagonal shape of stainless steel bars is essential to their usefulness and efficiency in different tasks and areas. This configuration, for instance, offers better load distribution than other lignatures, significantly reducing stress concentration during operations. This geometric property is advantageous in precision engineering when working on applications with critical tolerances and low material utilization, such as high-performance fasteners and connectors. From the information gleaned from these sites, I note that the standard configuration of hex bars makes their machining and automating of processes more manageable and, therefore, enhances production efficiency. As a result, these characteristics make hex bars necessary in every area, such as the automotive, aerospace, and manufacturing industries, where efficiency is crucial.

Why Choose Stainless Steel for Your Bar Needs?

Among the many alternatives available for bar applications, stainless steel is favored particularly for three informed reasons. To begin, it possesses an extraordinary inherent ability not to corrode, especially in areas constantly exposed to moisture, acid, or alkaline solutions, extending its functional life. This is due to the chromium content, which forms a passive film of chromium oxide, which protects the surface from corrosion. For instance, grades such as 304 can withstand corrosion under general exposure conditions, whereas grade 316, which contains 2-3 % molybdenum, should be used in more advanced environments, such as marine and chloride conditions. Secondly, stainless steel’s tensile and yield strengths are impressive; these measure approximately 485 MPa for 304-grade stainless steel and up to over 620 MPa for 316 types.

Additionally, the aesthetic value of stainless steel, along with its ease of maintenance, adds to its functionality for both practical and aesthetic uses. The microstructure of stainless steel is also favorable for easy fabrication and welding, which is required for complex and tailored projects. Therefore, these factors make stainless steel the most efficient and superior material in the construction, automobile, and chemical processing industries.

The Advantages of Cold-Finished Metal

The benefits of cold-finished metal are apparent when looking at the best available options, as it exhibits better mechanical characteristics and has better surface finishes. From my research, cold drawing causes a rise in tensile strength and yield strength owing to strain hardening. This means a more imposing metal that can bear higher stress and loads without distortion, which is paramount in most precision-engineering tasks. Overall, that means better dimensional accuracy and smooth polished surfaces, which are essential in manufacturing components within tight tolerances.

In addition, cold-finished metal also has marked improvements in machinability factors. The repetitive and predictable characteristics make machining more efficient and less expensive. This is often made possible because of the increased material uniformity along the cross-section. Cold drawing applies forces onto the metal to reduce the cross-sectional area by pushing it through dies, thereby altering its microstructure for better and consistent technical results.

The technical parameters demonstrated in cold-finished metal include an increase in tensile strength of 20 – 30% over hot-rolled representatives and surface finishes in the order of Ra 3.2 μm or better. Such improvements explain why cold-finished metal is dominating the industries where high-quality precision parts are required, i.e., in the aerospace and automotive industries.

How to Select the Right Stainless Steel Hex Bar for Your Project?

Finding the best stainless steel hex bar for your project is essential if you are looking to strike an excellent balance between functionality and cost. Start thinking about the particular environmental conditions the bars will be exposed to; for example, for general purposes, bars made from 304 stainless steel would be considered a good choice due to their excellent formability and resistance to corrosion. However, for a more aggressive environment, especially one with chlorides or long nautical exposure, 316-grade stainless steel would be preferred due to its anti-pitting and corrosion accommodation. Understand what the mechanical requirements of your application are – tensile strength and yield stress for working loads that will be most critical for your application. Check the dimensions for load-bearing efficiency and proper orientation in the application area. In addition, the surface treatments include aesthetics; a polished surface may be needed for looks or maintenance. Lastly, consider cost and time for availability based on how the market works, together with the delivery time for production, to ensure that the hex bar that has been selected does not exceed the financial as well as the functional limits.https://ssalloy-steel.com/blog/stainless-steel-rod/

Decoding the Different Grades: 303, 304, and 316

Choosing the correct rank of stainless steel for your assignment has its challenges, including studying each grade’s different properties and applications. Stainless steel 303 is known for its outstanding machinability, which is imparted due to sulfur, and it is reasonably competent when it comes to machine work that is detailed and intricate. However, this has a downside: the material is less corrosion-resistant. More popularly, 304 is one of the most widely applicable and extensively in use stainless steel as it has dependable anti-corrosiveness and other essential mechanical characteristics such as formability and strength with mechanical properties of 515 – 725 MPa tensile strength and yield strength 205 – 290 MPa. In contrast, 316 contains molybdenum, which enhances its pitting and corrosion resistance, making it suitable for use in more hostile environments such as the sea or harsh chemicals. It has a tensile strength of 485 – 620 MPa and a yield strength of 240 MPa. When choosing any of these grades, one must analyze the application’s specific environmental and mechanical conditions to get the best value for money, material, and performance.

Factors to Consider: Size, Length, and Specification

The selection of stainless steel products primarily involves considerations regarding dimensions and specifications for application. First, evaluate the size; this is such a minimum requirement as the diameter or the width that needs to be specified given the project’s needs, which touches on its ability to withstand loads and support the desired structures. Many applications may not need the standard sizes, but unique projects may require individualization, such as customized fabrication of particular tolerances to achieve the required fit. Two factors should be considered: the overall length needed for the uninterrupted sections and the transportability of pieces. Longer sections may lessen the necessary joints and improve structural stiffness.

In the specification, mechanical properties like tensile and yield strength are included and should be aimed at meeting or exceeding industry standards relevant to your use case. For example, 304 stainless steel is acceptable in most applications, as it has sufficient strength and good corrosion resistance. In terms of specific technological parameters, it is necessary to make sure that tensile and yield strengths are sufficient for operational stresses: 304-grade has a typical tensile strength distributed in the range from 485 to 620 Mpa; yield strength, on the other hand, has a typical range between 170 and 310 Mpa. As for the last point, requirements concerning surface finish should meet the criteria of aesthetic and maintenance function; for visible parts, polished finishes would be required, and in non-visible applications, a matte finish would be more appropriate. It is also essential to ensure that these parameters are consistent with the technical ones needed to optimize the material’s performance for a minimum cost.

Ensuring Quality: Material and Tolerance Specifications

When determining stainless steel products, one must always be cautious about the separate material and tolerances specifications. Those are the standards for the material quality. American Society for Testing and Materials standards would be an example: dealing with performers, functionality American materials have to be within its ranges. Also, it is necessary to choose steel grades corresponding to environmental and mechanical requirements. For example, grade 316 is known for its outstanding corrosion resistance and ideally fits marine conditions.

Tolerance is the term used for the range of variation allowed in physical dimensions, which is crucial to ensuring consistency and efficiency in operations. Tolerances are controlled by BA (Bright Annealed) or various other surface specifications based on the visibility determined. In the upper case, this parameter should meet the project’s needs so that all the components join correctly and keep tolerances of the order of ± 0.1 mm on the elements designed to achieve high precision. The technical parameters should be by international requirements, for instance, 515-725 MPa tensile strengths and yield strengths in the 170-310 MPa range for stainless steel 304: the combination of these parameters will allow the material to sustain the operational loading. Meeting the standards helps assure material quality and protection against possible material failure and ensures the product’s performance through its life cycle is excellent.

Where to Buy Stainless Steel Hexagonal Bars?

When selecting a distributor of stainless steel hexagonal bars, it is critical to know your priorities in terms of quality, specification, and delivery. Commercial distributors such as Grainger, McMaster-Carr, and Ryerson supply different grades and sizes of stainless steel hexagonal bars with a good reputation. Such suppliers are often expected to assist in providing more technical characteristics of the product, ensuring compliance with industry standards such as ASTM, which is critical for options that demand specific mechanical characteristics and tolerance. Besides, it is common for these suppliers to provide additional means of fulfilling your deadlines and budget limits. Other tailored options specifically for bulk purchases or custom orders would be through local producers or metal service shops in the area.

Finding the Best Rates Around for Your Steel Hex Bar

In my efforts to source steel hex bars with the best market rates, I lobby industry research and assessment of suppliers as my primary strategy. I look for well-known distributors, such as Grainger, McMaster-Carr, or Ryerson, and look for their special offers. Price lists of such companies usually have a significant number of pricing tables and offer several discounts for the quantity ordered, which can be beneficial. I also call a few local service centers and manufacturers for quotations since they are reasonably priced and are specific to project requirements. In this way, as well as factoring in transport and time for delivery, I can meet the most competitive prices for steel hex bars for my purposes.

Top Stores to Shop Stainless Steel Hex Bars

When selecting the top stores to shop for stainless steel hex bars, it’s critical to consider specific criteria, including reputation, product range, technical detail availability, and compliance with industry standards. The following stores emerge as leading options:

- McMaster-Carr: Known for its comprehensive selection of stainless steel hex bars in grades 304 and 316. Customers benefit from detailed technical specifications on tensile and yield strengths, ensuring the material meets ASTM standards. McMaster-Carr provides dimensions with tolerances maintained to precise specifications for hexagonal bars, often within ± 0.1 mm for tight engineering requirements.

- Grainger: Offers a variety of stainless steel hex bars with convenient online purchasing options. Grainger provides extensive technical documentation for each product, ensuring that industry standards regarding strength metrics and corrosion resistance are met. The availability of hex bars in standard lengths and custom sizes makes it a versatile choice for various applications, with options catering to trim and bulk orders.

- Ryerson: This supplier excels in providing standard and tailor-made stainless steel hex bars. Ryerson distinguishes itself by focusing on quality assurance and tailored client solutions, including custom-cut lengths and finishes to match project specifications. Each product is backed with relevant ASTM and ASME standards, highlighting important technical properties such as tensile strength, yield strength, and dimensional tolerances.

By leveraging these suppliers, buyers will receive high-quality stainless steel hex bars suited to industrial and commercial needs. The technical parameters offered by these stores ensure compliance with project specifications and industry requirements.

Online Services and Availability

- McMaster-Carr offers a diverse range of stainless steel hex bars online, with detailed technical information on each product. This ensures the material’s compliance with the industry standards such as ASTM. Their website allows for easy navigation and purchasing, with real-time stock availability and estimated delivery dates provided, helping me make informed decisions.

- Grainger also provides a comprehensive online platform for purchasing stainless steel hex bars. They feature robust technical documentation that aligns with strength and corrosion resistance standards. Grainger’s inventory system keeps options open for standard and custom orders, fulfilling various project needs with expedited shipping options.

- Ryerson stands out with its online services by offering standard products and custom solutions. Their platform ensures that detailed technical specifications, including dimensional and strength metrics, are available for each type of bar. They also provide the option for custom lengths and finishes, enabling precise adherence to project requirements.

By utilizing these websites, I confidently sourced the necessary materials that aligned with my technical specifications while also benefiting from clear availability and pricing transparency. This approach allowed me to meet my project timelines and budget constraints efficiently.

How to Cut and Use Stainless Steel Hex Bars in Projects?

It is essential to use the correct tools and techniques when cutting stainless steel hex bars for project applications to ensure accuracy and safety. First, choosing the right cutting tool, like a band saw or an angle grinder with a high-speed steel or carbide blade, is wise because they are perfect for cutting steel and stainless steel. After this, fastening the hex bar against a castle is critical to avoid movements during the cutting activity. Next, grab a scribe or a sharp marker and measure and mark the place that needs to be cut at the desired length. It is advisable to use a square or straightedge to ensure accuracy. Apply even pressure on the material while cutting to prevent overheating and thus avoid damaging the material.

Hex bars that have been cut may be used in mechanical functions such as supports, fastenings, and connectors, owing to their strength and corrosion resistance. It is advisable to use a file or deburring tool to improve the efficacy of the cut edges. This ‘cutting’ prevents any chances of sharp edges, which snag during assembly, thus improving the parts’ compatibility. Applying these simple instructions enables the efficient cutting of hex bars of stainless steel for incorporation in projects that meet engineering criteria and technical specifications.

Essential Techniques for Cutting Hex Bars

There are several requirements for cutting hex bars effectively, including precision, tool selection, and technical parameters. The first step is selecting the cutting tool: a band saw or angle grinder with a carbide-tipped blade, which could be pretty helpful in maintaining flat-tipped blades in stainless steel and have high tensile strength. This also requires securing the hex bar with clamps. So that they do not move around during the cut, calipers should be utilized to measure cut lengths so that the tolerance levels of the cut are in place with engineering requirements, typically ±0.1 mm unless specified before the project begins.

With a scribe or a fine-tip marker, the cut line can be marked, and a square can be employed to check whether the line is straight. Keep a moderate feed rate throughout the cut to prevent overheating of the tool, as this may reduce the cut’s quality and impact the hex bar’s mechanical properties. Power tools should be used after cutting procedures as well, such as deburring tools, which remove the burrs and safety requirements so that edges are round and cannot cause cuts on the skin. A final review of dimensional specifications and surface verification against the project’s necessary criteria should be undertaken. Technical and safety measures are followed by these procedures that enable Owen Magnus’s hex bars to function as per their designs.

Common Applications of Stainless Hex Bars

I found a lot of stainless hex bar applications in the industrial and engineering sectors. However, the engineering of such bars makes it possible to use them in constructing fasteners such as nuts and bolts, thereby increasing the strength and resistance to the effects of corrosion. Moreover, they are also used to produce supports and braces for machines operating under stress. In the automotive industry, stainless hex bars are also employed to manufacture components that need low weight but high strength due to their accuracy and toughness. To summarize, these bars are an essential part of the engineering process for any task that demands solid and dependable materials and, therefore, fit perfectly with my specifications and requirements. Their multi-functionality enhances their significance in areas where precision and strength are paramount.

Enhancing Projects with Bar Products

To provide functionality to my projects containing bar products. The websites examined pointed out the features of strength, accuracy, and resistibility to the surrounding environment, e.g., rust. For example, using stainless steel hex bars in my instances has enabled me to comply with some engineering requirements for tensile strength, standardized sizes, and thermal stability. I ensure compliance with technical parameters is in place and tolerances of precision elements are kept up to ±0.1 mm within the regime of the design order. These tolerances and metal-working technology ensure the proper installation of bar products in my designs and allow my projects to work under more than strict requirements.

What Are the Common Stainless Steel Grades Used in Hex Bars?

Considering the standard grades used for the applications of stainless steel hex bars is essential, as every steel grade’s properties differ. Phyletic, most often, the grades are 304, 316, and 303. A rate of 304 is accepted as the most adaptable and the basic one. This steel has very good corrosion resistance and good formability, making it suitable for a large variety of general applications. It ends grade 316, which is more corrosion resistant than 304 because of the addition of molybdenum, and outperforms grade 304, especially in salty water or chemical environments. It is, therefore, suited for most marine and some industrial applications. On the other hand, grade 303 is processed to provide improved machinability which makes it an easy grade to work with and therefore a good option for making precision parts. These stainless steel grades also have some more or less significant differences, allowing them to be used for various engineering applications and, therefore, enhance the respective structures’ strength and serviceability.

An Overview of 304 and 316 Grades

I realized that grades 304 and 316 will utilize grade stainless steel where strength and anti-corrosive properties are to be observed. Because of its incredible versatility, Grade 304 possesses great corrosion resistance, making it excellent for many general-use applications. As for grade 316, it is a camera with better performance in more corrosive environments where chlorides or industrial chemicals are typically found. The higher performance related to grade 316 can be associated with adding molybdenum, which enhances the anti-corrosion of two major corrosion types. There are good mechanical properties in grades 316 and 304, but 316 has slight superiority in more severe conditions, proving all grades ideal for a wide range of engineering structures with high load factors.

Comparing 303 and 304 Stainless Hex Bars

We can see that there are primary differences between the two grades of stainless steel hex bars, in this case, the 303 and 304 grades, mainly their composition and machinability. Grade 303 is a little more machine-friendly owing to the addition of sulfur. This grade is preferred for applications that require a lot of machining operations, but due to the addition, it will have slightly lower corrosion resistance than grade 304. On the other hand, 304 stainless steel provides better corrosion resistance than 303, and it is also easy to form into different shapes, which, in this case, makes it the most suitable grade for a range of construable applications. For instance, grade 303 mechanical parameters include tensile strength of 690 MPa, yield strength of approximately 345 MPa, and elongation of 50%. In comparison, grade 304 usually has a high tensile strength of around 620 MPa, yield strength of 215 MPa, and elongation of 45%. These values ensure that both grades effectively serve their purposes; however, it can be noted that 303 grade is more in precision machining, whereas 304 grade has variety in severe conditions.

Choosing Between 304 and 316 for Different Applications

I look into their particulars when choosing between 304 and 316 stainless steel hex bars. However, suppose the application involves high corrosive exposure, especially in contact with chloride or industrial chemical environments. In that case, I prefer grade 316 as it contains molybdenum content that increases its resistance to corrosion. However, for most simple applications, where using different shapes and good corrosion resistance is enough, grade 304 is the most appropriate. In practical terms, grade 304 usually provides a tensile strength of value of 620 MPa and a yield strength of 215 MPa, and grade 316 has a tensile strength of around 580 MPa with a yield strength of 290 MPa. These parameters enable selections to be made in a manner relevant to the prevailing conditions surrounding the structure and the strength requirements of the structure, thus allowing me to optimize performance against expenditure in any project.

Frequently Asked Questions (FAQ)

Q: What are stainless steel hexagonal bars?

A: Stainless steel hexagonal bars are long, six-sided bars made from stainless steel, known for their strength, corrosion resistance, and versatility in various applications. These bars are often used in construction, manufacturing, and industrial projects.

Q: How can I buy stainless steel hexagonal bars?

A: You can purchase stainless steel hexagonal bars from metal suppliers, online marketplaces, or specialized distributors. Ensure the supplier offers the specific size and grade you need for your projects.

Q: What are the common uses of stainless steel hexagonal bars?

A: Due to their strength and durability, stainless steel hexagonal bars are commonly used in the manufacturing of fasteners, such as nuts and bolts, as well as in the construction of structural frameworks, support rods, and precision machined parts.

Q: Can I buy stainless steel hexagonal bars in metric sizes?

A: Yes, stainless steel hexagonal bars are available in metric and imperial sizes, allowing you to choose the precise dimensions needed for your specific applications.

Q: Are stainless steel hexagonal bars available in stock?

A: Many suppliers keep stainless steel hexagonal bars in stock in various sizes and grades to ensure quick delivery for business and industrial needs.

Q: What grades of stainless steel are used for hexagonal bars?

A: Common grades of stainless steel used for hexagonal bars include 304, 316, and 303. Each offers unique properties, such as enhanced corrosion resistance or improved machinability, suitable for different business applications.

Q: How do stainless steel hexagonal bars differ from stainless steel round bars?

A: Stainless steel hexagonal bars have a six-sided cross-section, providing more surface area for grip and fastening, whereas stainless steel round bars have a circular profile, often used where uniform shape and diameter are required.

Q: Why choose stainless steel hexagonal bars over other stainless bar products?

A: Due to their shape, stainless steel hexagonal bars offer enhanced versatility and strength, making them ideal for applications requiring precise machining, strong fastening, and structural integrity.

Q: Can I purchase stainless steel hexagonal bars in multiple quantities?

A: Yes, stainless steel hexagonal bars can be purchased in multiple quantities, ranging from small batches to bulk orders, depending on your project requirements.

Q: What should I consider when choosing stainless steel hexagonal bars for a specific case?

A: When selecting stainless steel hexagonal bars, consider factors such as the grade of stainless steel, required dimensions, and the specific application to ensure optimal performance and compatibility with your project needs.