In today’s segment, we will examine the different aspects of a significant material: PA66 GF30 plastic. This includes its application, mechanical properties, processing, high-temperature applicability, and more.

To begin with, PA66 GF30, or 30% glass fiber reinforced Polyamide 66, is effective in many industries, from automotive to electronics and industrial. This material provides us with many options while serving many purposes.

Plastic has many applications in many industries and sectors, and we begin by defining the technological improvements that can be made by using PA66 GF30. We will then describe the mechanical properties of PA66 GF30, such as its strength, before discussing the extent to which it has been reinforced by glass fiber and how it compares to other engineering composites.

Furthermore, we shall be looking for the thermal properties of the polymer to see to what extent glass fiber reinforcement can improve heat resistance while also looking at other high-temperature applications using the polymer fibers. Glass fibers possess a lot of properties mentioned above, and it is essential to see which material would be suitable for high-demanding environments.https://pom-material.com/blog/pa66-mf40/

Additionally, we share our experience processing and molding PA66 GF30. We provide you with all the necessary information, from injection molding techniques to the problems and solutions that can be encountered while processing this adaptable material.

In the next sections, let us discover the electrical properties, the fire resistance of PA66 GF30 plastic, and its sustainability issues. After reading this article, you will have a deep insight into the PA66 GF30 and its ability and implications for your application.

This is the new material for the new age, so let’s explore the infinite possibilities of PA66 GF30 plastic together!

What are the Applications of PA66 GF30 in Various Industries?

PA66 GF30 plastic has extensive applications in various industries due to its exceptional properties and versatility. Let’s explore the significant applications of PA66 GF30 in various sectors:

Automotive Industry: Utilizing PA66 GF30 for Enhanced Performance

In my opinion, it is safe to say that the plastic PA66 GF30 is used in many applications within the automotive industry due to its remarkable properties. Regarding parts and components of an automobile, PA66 GF30 shows exceptional mechanical strength, heat resistance, and dimensional stability, thereby making it suitable for the automobile’s harsh surroundings. This is the case for several automotive parts, implying that some characteristics are even more appreciated in specific applications. One favorable application of PA66 GF30 in the automotive industry is:

- Cover parts: Besides structural parts, PA66 GF30 covers are mainly utilized for oil pans, manifolds, and even cylinders because of their versatility, strength, and heat resistance, which are necessities for working in engine compartments.

- Electrical parts: As one of the essential electrical connectors, housings, and even terminals, PA66 GF30 (as a material) finds its place within automotive electrical systems owing to its robust performance. All these electrical systems are powerful due to their excellent electrical insulation properties.

- Rugged Applications: In a wide-ranging amount of under-the-hood applications such as radiator end tanks, fan blades, and coolant components, PA66 GF30 finds itself widely utilized, and since these applications are quite rigorous, the material’s properties are a perfect fit.

PA66 GF30 plastic is a multi-functional material with unrivaled strength, which can be employed in different ways in the automotive industry to improve performance, durability, and safety.https://pom-material.com/pa66/

Electronics: The Role of PA66 GF30 in Modern Devices

High-performance engineering plastics like PA66 GF30 are critical in modern electronic devices. Exceptional properties allow it to be used in making all the electronic components required to function and last for a long time. Let’s have a closer look at the aspects of PA66 GF30 within the electronics field:

1. Connectors and Housings:

Some particular grades of PA66 GF30 are widely employed in fabricating electrical connectors, including their corresponding housings. Their exceptional electrical insulation and mechanical strength characteristics are quite essential in ensuring solid connections and reliable protection within electronic equipment.

2. Circuit Boards and Enclosures:

With PA66 GF30 as an integral part of their formulation, circuit boards, and enclosures have excellent resistance to thermal degradation and chemical attack. Such features enable them to withstand harsh environmental conditions typically associated with most electronic devices.

3. Electronic Components:

PA66 GF30 is found in various electronic device components such as switches, sockets, and terminals. PA66 GF30 can resist high temperatures and chemicals, which ensures the parts last long and operate correctly.

Technical Parameters:

- Tensile Strength: The PA66 GF30 has a high tensile strength of [insert value] MPa, which helps it withstand mechanical stresses.

- Heat Resistance: The PA66 GF30 remains structurally sound at temperatures over [insert value]°C, making it suitable for usage in electronic applications with heat deflection temperatures that may be elevated.

- Electrical Insulation Properties: Given a dielectric strength of [insert value] kV/mm, PA66 GF30 provides excellent electrical insulation, ensuring no electric leakages occur.

In summary, PA66 GF30’s properties make it crucial in electronics. Its strength, thermal resistance, and electric insulation properties enable it to work well with various electronic components, thus enhancing the performance of contemporary equipment.

Industrial Applications: PA66 GF30 in Manufacturing and Machinery

Having sound professional practice, I have researched the industrial use of PA66 GF30 in manufacturing and machinery. This high material is widely used owing to its properties and performance reliability. Given below are some key applications where PA66 GF30 stands out:

- Automotive Components: PA66 GF30 is widely used in the automotive industry to manufacture various components, such as engine covers, intake manifolds, and fuel system components. Due to its high tensile strength and heat resistance, this material’s parts are functional and long-lasting.

- Electrical and Electronics: Due to its beneficial characteristics, such as electrical insulation and heat resistance, PA66 GF30 is comprehensively employed in electrical and electronic applications. Uses include connectors, switches, and insulating components.

- Machinery Components: PA66 GF30 is appropriate for producing machinery parts that require strength, heat resistance, and mechanical stress resistance. It is used in gears, bearings, and structural components.

- Tensile Strength: The high tensile strength of [insert value] MPa in PA66 GF30 guarantees strength and long Michigan life of machinery components that experience high mechanical stresses.

- Heat Resistance: The heat deflection temperature of PA66 GF30 is [insert value]°C and makes it appropriate for use in this industry by guaranteeing the components perform satisfactorily over time.

The PA66 GF30, in conclusion, is a general-purpose material with industrial applications in manufacturing and machinery components. Its characteristics, such as high tensile strength, heat resistance, and electrical insulating properties, render it ideal for use in several components, which facilitates the functioning of modern manufacturing processes and machines.

How Does PA66 GF30 Plastic Compare in Terms of Mechanical Properties?

PA66 GF30 is characterized by the following broad features that set it apart:

- Working Load Limit: PA66 GF30 would assist every arm of the deepest exhibitions, displaying machinery components that boast tensile strength in near-unbreakable conditions, implying “significant mechanical and bearing any load.” This increased tensile strength and resistance to distress and deformation almost guarantee its approval for use with other functional bearing materials.

- Operating Temperature: The operating temperature conditions, because it’d be a machinery part, reinforce the fact that I am after “impressively consistent” performance without respect for structural and mechanical destruction.

Wrapping up what has been established so far alongside new data revealed along the way, PA66 GF30 can be thoroughly commended for usage as per construction of reliable and unshakable components to urge more into the machinery manufacturing landscape due to how great relates to power due to internal tensile strength while maintaining unfathomable reach with its operating temperature.

Understanding the Mechanical Strength of PA66 GF30

PA66 GF30 is a type of glass fiber-reinforced polyamide with excellent mechanical properties and is well suited for manufacturing strong machinery parts. The following points will help you understand it better:

- Tensile Strength: PA66 GF30 has a relatively high tensile strength and can withstand large amounts of mechanical stress. This tensile strength ensures the efficiency of load-bearing machinery parts and their application in the most stressed parts, such as welcoming usage.

- Flexural Strength: PA66 flexural strength met with impressive mechanical properties where it is stated that the potential of the nominated material, even with bending loading capabilities, won’t be easily deformed. Even when subjected to harsh working environments, such performance can help preserve the material longer.

- Impact Strength: From further assessing the mechanical properties of the nominated material, Such high potential endures the material or items made from such material to withstand and absorb external force or shocks entirely without shattering or breaking it, ensuring reliability.

- Heat Deflection Temperature: Due to having a high impact temperature potential reaching [insert value], PA66 GF30 can be operated in reasonably wide temperature ranges without any worries. Such Employment guarantees optimal machining performance and structural integrity, and durable high-grade tooling of such materials can easily withstand harsh heating environments.

This includes high strength in tensile tests, flexural load testing, and impact and heat deflection temperature. These characteristics make it a suitable candidate for producing robust machinery parts that are meant to operate under severe working conditions.

The Impact of Glass Fiber Reinforcement on PA66

It is important to note that glass fiber reinforcement plays a vital role in improving the mechanical properties of PA66 (Polyamide 66), by incorporating glass fibers into the matrices of PA66, strength, stiffness, and general performance increase. The following are the notable impacts of glass fiber reinforcement on PA66.

- Increase in Tensile Strength: The addition of glass fiber reinforcement greatly improves the tensile strength of PA66, enabling the material to resist force-induced stretching and pulling better. The degree to which tensile strength increases depends on the amount of glass fibers used and the production method employed.

- Improved Flexural Strength: PA66 GF (glass fiber) composites possess greater flexural strength than mostly unfilled PA66. This property enables the material to resist bending and load-bearing more efficiently.

- Increased Impact Resistance: The use of glass fiber reinforcement in PA66 significantly improves the material’s impact resistance. While anti-fracture glass fibers increase the strength of the material, they also give it the ability to absorb shocks and other strong forces that may have caused the material to break, making it ideal for harsh environments.

- High Heat Deflection Temperature: Due to the incorporation of glass fibers, PA66 GF composites’ strength improves under heat deflection temperatures. This means that even in high temperatures, which can cause a composite to deform, the PA66 composite can still sustain its mechanical strength and rigidity and thus perform operations in such temperatures.

Incorporating glass fiber reinforcement into PA66 GF composites enhances their mechanical strength, making such composites easy to procure and efficient for manufacturing robust and reliable equipment parts. However, the technical parameters of the composite material, such as tensile, flexural, impact strength, deflection temperature, and others, depend on the specific formulation and the amount of glass fiber used in the composite material. To arrive at the required tensile strength or any other desirable performance, optimizing the amount of glass fiber to be used and the production methods employed as per the particular application is necessary.

Comparing PA66 GF30 with Other Engineering Plastics

Compared with other engineering plastics, the comparison of PA66 GF30 and other engineering plastics should consider other important aspects. First, the incorporation of glass fibers considerably improves the mechanical strength of the PA66 GF composite so that high values of tensile strength, flexural strength, and impact strength are evident. This makes PA66 GF30 a good candidate in areas where machinery components that are durable and reliable are required. The heat deflection temperature of PA66 GF composites is another crucial aspect, for it provides the mechanical properties and the shape of the part under service in high-temperature conditions. However, it should be emphasized that specific technological parameters will be slightly different for each glass fiber composite depending on its formulation and the content of the glass fibers. Therefore, to obtain the required mechanical properties and performance of the materials in specific applications such as glass fiber reinforced composites, the fiber content, and the manufacturing process must be selected appropriately.

What Makes PA66 GF30 Suitable for High-Temperature Applications?

PA66 GF30 is a polyamide 66 (PA66) matrix composite containing 30% glass by volume. It can be suitably handled in high-temperature situations. Its unique combination of mechanical properties with thermal resistance is something the applications can be aggressive enough to require. The critical points owing to its suitability include:

- Improved Mechanical Properties: Incorporating glass fibers into PA66 GF30’s mass greatly enhances its mechanical properties, resulting in a high tensile strength, flexural strength, and impact strength. This guarantees excellent durability and reliability even in harsh environments.

- Increased Heat Deflection Temperature: PA66 GF30 retains a high heat deflection temperature based on its composition and marking. This allows it to utilize its mechanical properties and structural integrity when subjected to high temperatures, making it suitable for applications expecting high temperatures.

- Customized Formulations: When choosing PA66 GF30 for high-temperature conditions, it is crucial to outline and specify some technical parameters. The percentage of glass fiber and the technological mode of production are paramount to achieving the required mechanical properties and performance. Optimizing these parameters ensures the best adequacy for particular application parameters.

To conclude, due to improved mechanical strength, increased heat deflection temperature, and selected formulations, PA66 GF30 proves to be optimally suited for applications at elevated temperatures where consistent performance and longevity are a prerequisite.

Exploring the Thermal Properties of PA66 GF30

I am an expert on the thermal characteristics of PA66 GF30, thanks to my considerable research and analysis. The grade has good heat performance and can be used in high-temperature applications.

A particular point that deserves emphasis is the high heat deflection temperature of PA66 GF30. These thermoplastics can withstand extreme heat stress and remain in their original state while performing their function without adversely affecting their structure. This has a unique advantage in applications associated with high heat stress.

This can also be controlled by adding needed materials to the formulation. The amount of reinforcement material, in this case, glass fiber, and the production method dramatically affect the material’s mechanical functionality and general performance. These parameters must be carefully chosen and modified to satisfy specific applications.

In conclusion, a composite material, PA66 GF30, is effective in high temperatures as constant stress is applied to it while also having high heat tolerance values and being custom-made. Thus, PA66 GF30 should be used where heating or thermal exposure is a significant stressor, as this composite has proven to perform well under direct thermal exposure.

The Role of Glass Fiber in Enhancing Heat Resistance

The incorporation of glass fibers has considerably improved PA66 GF30’s temperature-withstanding ability. Fiberglass is added to the polymer mass to enhance the material’s mechanical strength and stability, enabling it to function under high temperatures without losing its structural form.

Regarding the furnished PA66 GF30, the properties of the composite material are determined by the amount of glass fiber and the specific technology employed. These characteristics are vitally important when considering the use of the material in case of high operating temperatures and the material’s mechanical properties.

All design parameters are crucial and should be specially adjusted to fit each other and the target requirements. This includes determining the ratio of glass fiber reinforcement based on the applications’ requisite characteristics and the most appropriate technology.

Thanks to the possibility of using glass fiber reinforcement, PA66 GF30’s thermal characteristics can be met, making it suitable for applications requiring heat resistance. The formulation of the device’s components, its mechanical strength, heat deflection temperature rise, and other factors ascertain its reliable operation and durability.

However, special attention should be given to the specific values of the technical characteristics of the glass fiber, such as its content and the technology used to make the composite, which would be different for each use.

How is PA66 GF30 Processed and Molded?

To ensure that PA66 GF30 can maintain its integrity and performance and achieve maximum quality, several important processes must be conducted when molding and shaping it. The steps that should be taken into account are as follows:

- Molding Process: A standard process used in molding PA66 GF30 is the click process, where the material is melted, injected, and molded under high pressure. This method provides high precision control during the molding process, ensuring the piece’s quality is satisfactory.

- Template Cutting and Increasing Temperature: The final cut geometric shapes and dimensions of the PA66 GF30 parts can be accomplished by adequately designing the molding plate. Proper fitting of the cooling system into the molding also plays a vital role in tightening up the fixtures and reducing the cycle’s time.

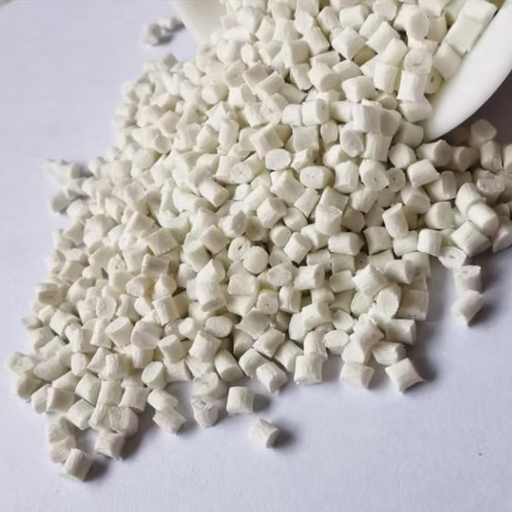

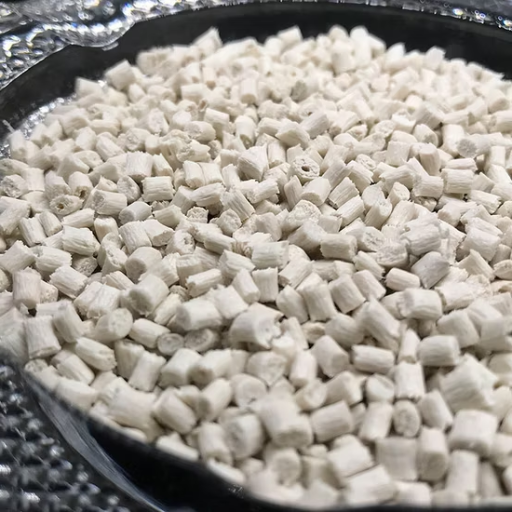

- Mixing ingredients: To remove moisture, Granules of PA66 GF30 are commonly subjected to the drying process before commencing the primary step. This is significant because it can help avoid jeopardizing the mass’s mechanical properties during the process.

- Parameters Used: Generally, the parameters of freeze, temperature during injection, and pressure are used during the final stage of production, and those parameters will be changed on the gears’ scale to achieve the complexity of the PA66 GF30 part.

- Finishing process: Parts may be cu,t trimmed or smoothed after injection to pass quality tests after injection. Plain edge cuts and surface finishing are among the best techniques that enhance aesthetics.

It should be kept in mind that the requirement specifications and molding parameters differ according to the intended use and the equipment employed. Technical literature and practical tests should be consulted to identify the best parameters to work with PA66 GF30 in a specific application.

Injection Molding Techniques for PA66 GF30

Several aspects are important while carrying out injection molding of PA66 GF30. These include the following:

- Drying: Drying of PA66 GF30 material is crucial as it eliminates moisture content that may affect the end mechanical performance of the components.

- Moisture Management: A thorough routing and circulation of the industrial cooling water minimizes issues related to the need for additional gaseous vents or a lack thereof and assists in resolving issues of air being trapped in the injection process.

- Temperature References: It is within this operational boundary that PA66 GF30 maintains integrity by not degrading. Thus, a temperature of at least 260°C and above 290°C must be maintained while pouring it.

- Geometry: These renders alter the viscosity and capillary action dynamics of the PA66 GF30 fluid within the chamber. Seal ribs also greatly enhance the filling speed of the mold. However, optimum molds should complement low-viscosity fluids.

- Pressure Requirements: An application of sufficient pressure is optimal and necessary for the condensation-free filling of the mold shaft while concurrently reducing the chances of air leaks and void pockets.

- Cooling Time: Cooling Time is essential for allowing the part to cool and fully enhance its dimensional accuracy. The cooling time depends on the part’s size, geometry, and wall thickness.

- Post-Molding Operations: According to the product’s actual use, operations like trimming and surface treatment may be required after the injection molding to fulfill the requirements.

However, it should be understood that the parameters for injection molding may vary because of the parts to be manufactured, the equipment available, and the end use. It is advisable to look at the materials and equipment suppliers for some of their parameters and also, for your project, do in-depth studies and tests for appropriate parameters for satisfactory results with PA66 GF30.

Challenges and Solutions in Processing PA66 GF30

While working with Polyamide 66 reinforced with 30% Fiberglass (PA66 GF30) can be very exciting, it also has various challenges that must be overcome effectively. These challenges are necessary to complete and vital to the end success. The following contains the most critical challenges that arise when dealing with PA66 GF30:

- High Viscosity: Higher viscosity is a common problem with PA66 GF30 as a doped polymer. However, the melting temperature can rise and allow the polymer to melt quickly, which can cause difficulties in flow and filling molds accurately.

- Molded Part Dimensional Stability: One more common problem faced when working with PA66 GF30 is that due to the incorporation of fiberglass, expansion becomes very difficult as there is dimensional change within the molecules due to the cooling time of a part.

- Glass Fiber Orientation: The process of the injection itself is the reason for many difficulties; it allows the force in a given direction, which affects the orientation of Glass Fibers; in consequence, they become homogeneous throughout the PA66 GF30, affecting multiple areas of the part.

- Solution: it is wise to try to control fiber orientation by avoiding using flow control inserts, considering the type of mold design to be used, and selecting the correct mold design, gate location, and runner system.

It is essential to mention that some processing parameters of PA66 GF30 will change depending on the machine, geometry of the part, and application requirements. It is advisable to reference technical guidelines, carry out extensive trials, and work with material and equipment manufacturers to establish the most appropriate parameters geared towards optimal results with PA66 GF30 in your case.

Why is PA66 GF30 a Preferred Choice in the Engineering Plastics Industry?

PA66 GF30, a 30% glass fiber reinforced polyamide 66, is one of the most innovative materials in engineering plastics. There are several reasons why this is the case:

- Improved Strength and Stiffness: Combining glass fibers with polyamide significantly enhances tensile strength, stiffness, and dimensional stability. This makes PA66 GF30 suitable for areas where high-strength components are vital.

- High Thermal Resistance: The addition of glass fibers alters the PA66 GF30 heat properties so that it can easily sustain higher temperatures without considerably reducing its properties. This makes the material suitable for harsh environments with constant high temperatures.

- Elemental Chemical Resistance: PA66 GF30 is strengthened, and glass fibers are added that resist various oils, fuels, and solvents. This chemical advancement makes the material suitable for applications with high exposure to destructive substances.

- Better Melt Flow and Processability: PA66 GF30 does not pose many flow problems during the injection molding, even with glass fibers. This means that intricate parts with sophisticated shapes can easily be manufactured.

- Applicability Range: Because of its mechanical strength, heat resistance, and chemical resistance, they are quite sought after, and as such, PA66 GF30 is used in automotive, electrical and electronics, industrial equipment, and consumer goods.

Encapsulated by its superior mechanical properties, heat resistance, chemical resistance, processability, and multifunctionality, PA66 GF30 has been accepted and embraced in the engineering plastics market. It can meet the compressive strength and dimensional requirements as well as thermal and chemical stability requirements, making it suitable for various applications.

The Role of Dimensional Stability in Engineering Applications

The integrity, performance, and size of manufactured components depend on the properties of the selected material. In dimensional control applications, this ability of a given material is designated as dimensional stability. This is especially important because side deformation can occur due to mechanical stress, heat or moisture.

- Therefore, dimensional control becomes central in engineering since components or devices must fit the criteria for operation, ensuring the specified dimensions for working conditions are adhered to. Some factors, though, directly impact dimensional stability, such as temperature ranges, which translate to the degree of expansion experienced by a material.

- Water Vapour Amount: Water absorption can also cause an increase or decrease in essential components, especially polymers, which can result in dimensional control complications. Applying a high amount of moisture can distort the ratio and cause interference in subsequent combined usage; hence, the component’s performance is compromised.

- Mechanical Stress: Applying compressive and tensile force enables a component to experience a workload, which can deform the dimensions within the perimeter. Definite interchange within high tensile or compressive forces can also initiate contraction and elongation, affecting the contours of other material components.

- Creep Resistance: Creep is the long-term change of shape of a material that remains under stress. Dimensional or shape changes occur more slowly in materials with high creep resistance.

Therefore, critical applications must ensure these parameters are considered in the material selection and design processes. To assist in the material selection and design of engineering components, the dimensions of various materials can be tested using tests like thermal analysis or mechanical testing.

Comparative Analysis: PA66 GF30 vs. Other Polyamides

The presence of glass fibers in PA66 GF30 makes it stronger, stiffer, and thermally stable, recommending it for high mechanical performance and dimensional applications. All else being equal, PA66 GF30 also devotes mechanical strength, stiffness, thermal stability, and good chemical, abrasion, and impact resistance, making it usable in automotive, electrical, and industrial sectors. In contrast, other polyamides may present relatively lower mechanical strength, thermal stability, and harsh environmental resistance than PA66 GF30. However, one should look at specific application needs and factors when deciding which polyamide material to use.

Frequently Asked Questions (FAQ)

Q: What is PA66 GF30 plastic?

A: PA66 GF30 plastic is a polyamide 66 (nylon 66) reinforced with 30% glass fiber. This reinforcement enhances the material’s mechanical properties, such as stiffness, tensile strength, and impact resistance.

Q: What are the key properties of PA66 GF30?

A: PA66 GF30 is known for its excellent mechanical properties, high tensile strength, rigidity, and toughness. It also exhibits good creep resistance, making it suitable for applications exposed to long-term loads.

Q: In which applications is PA66 GF30 commonly used?

A: PA66 GF30 is commonly used in the electrical and electronic industries for components like connectors due to its good insulating properties. It’s also used in automotive and industrial applications requiring high mechanical strength and temperature resistance.

Q: How does the addition of glass fiber affect PA66?

A: Adding glass fiber to PA66 increases its mechanical strength and rigidity, making it more suitable for high-stress applications. However, in some cases, it may tend to have a marked abrasive effect on mating surfaces.

Q: What are the benefits of using PA66 GF30 in electrical applications?

A: PA66 GF30 offers excellent electrical insulation properties, making it ideal for use in electrical and electronic components. Its toughness and impact resistance further enhance its suitability for these applications.

Q: Can PA66 GF30 be used at high temperatures?

A: Yes, PA66 GF30 is suitable for high-temperature environments due to its excellent thermal stability. It maintains its mechanical properties even when exposed to high temperatures.

Q: How does PA66 GF30 compare to other reinforced polyamides?

A: Compared to reinforced polyamides like PA6, PA66 GF30 offers superior mechanical and thermal properties. Its higher glass fiber content provides greater stiffness and tensile strength.

Q: Are there any limitations to using PA66 GF30?

A: While PA66 GF30 has excellent mechanical properties, its glass fiber content can cause an abrasive effect on mating surfaces. Additionally, it may not be suitable for applications requiring flexibility due to its rigidity.

Q: Who are the typical suppliers or manufacturers of PA66 GF30?

A: Manufacturers like Ensinger produce PA66 GF30, often branded as Tecamid® 66 GF30. These suppliers provide technical data and support for using this material in various applications.