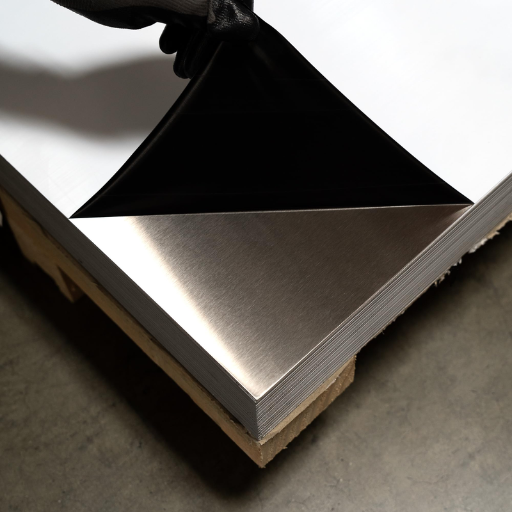

The most excellent steel sheets available today are 4×8 sheets of stainless steel due to their multiple advantages in several industries. This article is helpful to two groups of people–those looking to purchase a 4×8 stainless steel sheet metal and those looking to learn about this 4×8 stainless steel sheet metal. The former outlines the key characteristics, production methods, and performance that would satisfy the requirements of potential buyers. The article also outlines the different grades of 4×8 stainless steel sheet metal and the other finishes available. It helps choose the appropriate steel sheet type for the intended application. The article also addresses industry standards associated with 4×8 stainless steel sheets, detailing the best practices that should be deployed during the installation of the metal to enhance its performance and extend its lifetime. If you’re a professional or a casual ‘do-it-yourself’ enthusiast, this is your guide. This guide presents everything you need to know about 4×8 stainless steel sheet metal to make informed choices.https://ssalloy-steel.com/stainless-steel-sheet/

What Are the Key Features of 4×8 Stainless Steel Sheet?

Among the several applications of the 4×8 stainless steel sheet, some distinctive features have been noted to make it very popular. First, high tensile strength and the absence of stress deformation processes make the structure more durable. Chrome has been proven to be a practical alloying element as it passivates the surface with a fine chromium oxide film, preventing rusting or degradation. Coupled with this, the material also demonstrates a substantial degree of thermal resistance, which makes it applicable in high or low-temperature settings. The high gloss mirror surface of stainless steel also helps define it as a material that can be used for decorative purposes. Also, since stainless steel sheets have excellent plasticity and weldability, they are easy to manufacture and assemble into more complicated structures. All these combined, the 4×8 stainless steel sheet becomes the ultimate solution in various applications from architecture and the automotive industry.

Understanding the Alloy Composition

I shall turn to its constituent materials and ratios to comprehend the alloy structure of 4×8 stainless steel sheet metal. Stain steel alloy composition usually contains iron and chromium of at least 10.5 percent. The chromium content is essential because it provides the needed corrosion resistance properties through the superficial formation of a chromium oxide layer. As well as chromium, other constituents like nickel, molybdenum, and manganese may be included to improve toughness, specific chemical resistance, and strength, respectively. For example, nickel is used to enhance flexibility and provide resistance to steel corrosion, whereas molybdenum is utilized to improve pitting corrosion tolerance. The exact composition of alloying elements establishes the easy grade of stainless steel and alters its properties and areas of application. I appreciate the importance of enhancing the appropriate material resistance for the desired application and efficiency in the intended application.

Exploring the Corrosion Resistance Properties

The 4×8 dimensions of the stainless steel sheet metal have enough corrosion resistance to make it perfect for use in harsh conditions. This has high resistance because it has more than 10.5% chromium content. A strong, adherent protective layer of chromium oxide is formed on the surface, which helps protect the metal substrate from rust and corrosion. To put some technical terms in this passive film, it is only around 2 to 3 nanometers thick on average, yet it can quite effectively keep corrosives away from the steel. Nickel and molybdenum contribute even more to the protection against corrosion. In this case, nickel improves the strength and durability of steels in acidic conditions, and molybdenum enhances pitting and crevice attack resistance in chloride-containing environments, which is critical in marine applications.

Key parameters involved in assessing and ensuring the corrosion resistance of stainless steel include:

- Chromium content: Minimum 10.5% for effective passivation.

- Nickel content: Ranges between 8-12% for enhancing resistance to acids.

- Molybdenum content: Typically 2-3% to counteract pitting in saltwater environments.

- Corrosion Rate: A typical rate for high-quality stainless steel in corrosive environments is less than 0.002 inches per year, indicating high resilience.

For optimal corrosion resistance, careful selection based on environmental exposure and mechanical requirements is essential. This aligns with industry-specific standards and best practices, ensuring not only longevity but also safety and structural integrity in applications ranging from food processing to marine engineering.

Why Choose 4×8 Stainless Sheet Over Other Types?

The 4×8 stainless steel sheet offers several compelling advantages over other sheet metal types when selecting materials for construction, manufacturing, or decorative projects. Its unmatched corrosion resistance, robust strength, and aesthetic versatility primarily make it an exceptional choice. Stainless steel sheets are preferred for their durability and long lifespan, significantly reducing maintenance and replacement costs in various applications. The uniform 4×8 size allows for efficient material utilization and less waste during fabrication, making it a cost-effective option for large-scale projects.https://ssalloy-steel.com/blog/stainless-steel-sheet/

Technical Parameters:

- Corrosion Resistance: Excellent due to a minimum 10.5% chromium content. Chromium forms a protective oxide layer that significantly reduces corrosion rates.

- Strength and Durability: Exhibits high tensile strength, crucial for load-bearing applications, coupled with flexibility and toughness for structural integrity.

- Heat Resistance: It maintains structural properties in temperatures up to 1,400°F (760°C), making it ideal for high-temperature environments.

- Nickel Content Ranges between 8% and 12%; it enhances material performance in acidic and chloride-rich environments, such as marine settings.

- Molybdenum Content: 2-3%, added for enhanced pitting and crevice corrosion resistance.

These attributes collectively make the 4×8 stainless steel sheet an optimal material for diverse needs, including architecture, automotive, and industrial uses. Its adaptability and broad range of applications span from structural frameworks to sleek, modern design elements, ensuring performance and aesthetic appeal.

How Is Sheet Metal Used in Industrial Applications?

The stainless steel sheet metal 4×8 is used in heavy industries for its strength, functionality, and ability to withstand various conditions. Its application is found in many industries, such as food, chemicals, and transportation. For food processing purposes, stainless steel sheet metal is preferred because it does not react with food substances and helps keep equipment and machines hygienic. The oil and gas industry uses it for its excellent resistance to corrosion of cuts and the effects of harsh environmental elements on the pipelines and storage tanks . Moreover, it is used in the automotive industry to produce automotive parts, such as exhaust systems, which need high-temperature and corrosion-resistant materials. Stainless steel can readily be shaped and welded into parts and components designed to exact specifications, hence their use in industrial applications where dependable and efficient processes are required.

Popular Industrial Uses of 4×8 Stainless Steel

The 4×8 stainless steel sheet is quite popular in industrial operations because of its excellent qualities. First, food processing is invaluable due to its corrosion resistance and low maintenance. It makes sure that sanitary conditions are maintained and no contamination is introduced. The material can withstand many reactive agents in the chemical sector, enabling it to be used in building storage tanks and chemical pipes. Finally, its structural strength and capacity to withstand high temperatures and corrosive environments make it ideal for manufacturing automotive exhaust systems, thus exhibiting its usefulness in different industries.

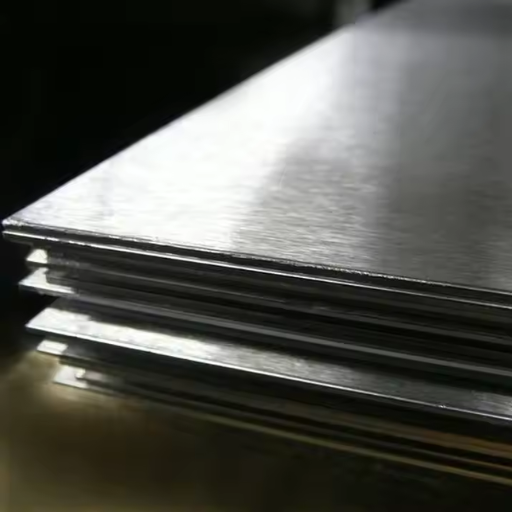

The Role of Thickness and Gauge in Application

Regarding the dimension and other parameters, such as the gauge of the 4×8 stainless steel sheet, its applications and resulting performance in different industries are affected. In most published papers on materials engineering, the optimum thickness is the one that guarantees and suits the operational requirements expected in the performance, like rigidity or even flexibility from the sheet. A thicker gauge would be optimal for durable heavy-index load-bearing applications in construction or automobile parts. Thinner sheets, however, are ideal for precision, lightweight applications like certain parts in electronics and appliances.

When determining the thickness and gauge, the American Iron and Steel Institute standards associate the gauge number inversely with the thickness; therefore, sheet thickness decreases as the gauge number increases. The technical parameters to be taken into account include:

- Thickness Range: Thickness is typically measured in millimeters (mm) or gauge; standard thicknesses for industrial applications often range from 0.5mm to 6mm.

- Load Capacity: The thickness determines the sheet’s ability to support weight without deformation.

- Flexibility: Thinner sheets offer greater flexibility and are suitable for forming and detailed fabrication work.

- Corrosion Resistance: While intrinsic due to chromium content, thicker sheets provide added longevity in corrosive environments.

Utilizing these parameters allows for optimized selection tailored to the specific needs of industrial projects, thereby ensuring both efficiency and structural integrity in demanding environments.

Environmental Considerations in Sheet Metal Usage

Sheet metal usage, mainly stainless steel, has an environmental impact on sustainable industrial practices. When evaluating the environmental considerations of using 4×8 stainless steel sheets, several factors and technical parameters should be taken into account:

- Recyclability: Stainless steel is 100% recyclable. At the end of its life cycle, it can be repurposed without degradation in quality, significantly reducing its environmental footprint. Recycling parameters should focus on the ease of separation from other materials and the efficiency of recycling processes.

- Energy Consumption: Producing stainless steel requires considerable energy due to the high temperatures in smelting processes. Choosing suppliers using energy-efficient or renewable energy sources can mitigate this impact.

- Byproduct Management: The creation of stainless steel generates byproducts such as slag, dust, and fumes. To minimize pollution, industrial operations should establish efficient air filtration and wastewater treatment systems.

- Longevity and Durability: Stainless steel requires less frequent replacement and maintenance due to its corrosion resistance and strength. This longevity reduces material consumption over time and lessens the demand for natural resources.

- Material Sourcing: Sustainable sourcing involves selecting suppliers who follow ethical mining practices and reduce their carbon footprint through responsible supply chain management.

These parameters underscore the importance of incorporating environmental principles into the selection and application of sheet metal in industrial activities. By prioritizing sustainability, industries can enhance their ecological responsibility while maintaining operational efficiency.

Comparing 304 and 430 Stainless Steel Sheets

Several differences can be pointed out for the 304 and 430 stainless sheets of metal, comparing them with each other, and every difference shows which kind of material is suited for which task. Performance-wise, both types are durable and possess anti-corrosive properties. However, 304 belongs to the austenitic composition family, which makes it more robust because it contains nickel and a more significant amount of chromium, making it more resistant to rust and harsh chemical environments. Because of this property, 304 is used in many applications that require excellent resistance to corroding elements, such as marine and chemical processing applications. On the other hand, Ferritic alloy 430 stainless steel contains less nickel, which makes it much cheaper. Still, it has lower usability in severe conditions, requiring moderate corrosion resistance and excellent formability. Also, 430 stainless steel is frequently used in automotive trim and some household appliances due to its magnetic and beauty properties. Therefore, selecting one of these grades depends primarily on the application’s specific requirements in terms of cost, the environment they are supposed to work in, and the needed mechanical properties.

Differences in Corrosion Resistance and Magnetic Properties

There are apparent differences in comparing the corrosion process and magnetic characteristics of the AISI 304 and the AISI 430 stainless steel sheets. The 304 stainless steel is non-magnetic owing to its austenitic structure, which contains nickel and high chromium (18% and above). This composition increases corrosion resistance, so it has reputable applications in marine and acidic environments. Its non-magnetic characteristic is beneficial in electrical and electronic installations where magnetic interference is to be avoided.

On the other hand, 430 stainless steel is ferritic with a chromium content of about 16 to 18% and no nickel, thus having moderate corrosion resistance. When compared to 304 in very extreme conditions, 430 is significantly weaker. However, its corrosion resistance is adequate for indoor, dry applications, including kitchen or automotive interiors or finishing. In addition, 430 can exhibit magnetic properties, which could be helpful in a situation where magnetic properties are required, such as fastening and joining methods.

The technical parameters to consider include:

- Chromium Content: 304 boasts around 18% chromium, providing enhanced corrosion resistance compared to 16-18% in 430.

- Nickel Content: Present in 304, absent in 430, influencing corrosion resistance and non-magnetic properties.

- Magnetic Response: 304 is non-magnetic, while 430 exhibits magnetic properties, influencing its suitability across diverse applications.

These nuanced differences inform the selection of appropriate stainless steel grades based on environmental exposure, cost considerations, and specific application requirements.

Applications Best Suited for 430 Stainless Steel

In my work as an industry expert, for moderate corrosion resistance and magnetic property applications, 430 stainless steel will do just fine. It has so many applications for household use for kitchen appliances such as dishwasher panels, refrigerator doors, and oven liners, where it withstands many temperature changes and looks quite shiny, too; it does this excellently. 430 is a standard grade in trim and molding applications in the automobile industry due to its good formability and aesthetic appeal. Because of its magnetic characteristics, it can be used for electrical applications where it may be favorable to have some magnetic interference. As a general rule, 430 stainless steel can be seen as a practical solution in environments that do not require the extreme resistance properties that 304 stainless steel and other higher-grade alloys possess, thus enabling compromises to the economics of the respective manufacturing process environments.

Cost Comparison: 304 vs 430

In my professional assessment, the cost disparity between 304 and 430 stainless steel is primarily driven by their composition and the intended applications for which they are used. 304 stainless steel, due to its austenitic structure and higher nickel content, tends to be more expensive. This additional cost stems from the enhanced corrosion resistance and durability it provides, making it ideal for demanding environments. Conversely, 430 stainless steel is more economical owing to its lower nickel content and ferritic structure, which limits its corrosion resistance but suits less rigorous applications.

When analyzing the financial implications, technical parameters to consider that impact cost include:

- Material Composition: The nickel component 304, absent in 430, significantly increases its price.

- Performance Requirements: Applications requiring superior corrosion resistance typically warrant a higher investment in 304.

- Production Volume and Market Demand: Bulk purchasing and industry demand influence cost fluctuations.

Ultimately, 430 Stainless offers a budget-friendly alternative for scenarios where its mechanical and cosmetic attributes suffice, balancing economic constraints with functional adequacy.

What Are the Decorative Uses of Stainless Steel Sheets?

Due to their visual appeal, versatility, and long-term durability, stainless steel plates, especially the 4×8 sheets, are extensively used in decorative applications. For example, they are used in building parts, such as wall coverings, internal plates or panels, and elevator doors, where their shiny surface is functional but does not compromise their durability. Modern kitchen designs use stainless steel in backsplashes, countertops, and kitchen appliances for an up-to-date aesthetic and easy cleaning. In addition, stainless steel is used in railings and fittings for decorative elements in the hospitality industry because of its beautiful appearance and high resistance to scratches, stains, and other damage. Artists and sculptors apply its formability and attractive surface to make beautiful and durable installations and sculptures out of the material. The numerous finishes, which include brushed, mirrored, and etched, increase its decorative prospects, allowing the designers to improve its application to suit different styles.

Using 8 Mirror and 4 Brushed Finish for Aesthetic Appeal

One can consider the two different finishes of stainless steel applications: an 8-mirror finish and a 4-brushed finish. This finish is famous for architectural applications and is commonly used for decorative wall panels, signs, luxurious interior finishes, or any other applications with a reflective surface. The 8-mirror finish, however, is most preferred as it eases the blending with other building materials. This finish also makes signing prominently visible owing to the satin reflective ability. Stamped or smooth stainless steel surfaces are popularly fitted in lift panels where smudges and blemishes are not displayed. However, when cutting through material, the four-brushed finish gives satisfying results since it makes the edges look flawless and smooth. Overall, the choice of finish entirely depends on the aesthetics required and how much wear and tear maintenance will be needed.

How PVC Film Enhances Decorative Applications

PVC film enhances the aesthetic and functional properties of stainless steel surfaces used in decorative applications. It provides a protective layer that guards against scratches, fingerprints, and other handling damages during fabrication and installation. This protection is imperative in maintaining the pristine appearance of eight mirrors and four brushed finishes. Additionally, PVC film can add a layer of UV resistance, enhancing the longevity of decorative elements exposed to sunlight.

When evaluating technical parameters, one should consider:

- Thickness and Adhesion: The thickness of PVC film can range from 60 to 100 microns, with varying levels of adhesion to ensure adequate protection without leaving residue.

- Transparency and Color: Depending on design requirements, PVC film is available in transparent or colored options to match specific aesthetic goals.

- Temperature Resistance: Films should withstand temperature variations without degrading, favoring environments with consistent thermal changes.

Ultimately, using PVC film is essential for safeguarding stainless steel’s visual integrity and extending the lifecycle of decorative applications in diverse environments. Its strategic application enhances the material’s usability across architectural and design contexts, reaffirming its value in enhancing spaces’ aesthetics.

How to Select the Right Stainless Steel Sheet for Your Kitchen?

While considering some factors essential for the design and functionality, a proper stainless steel sheet for the kitchen has to be selected. For example, the kind of stainless steel one needs now has to be defined; grade 304 is a very durable attachment, while grade 430 is a cheaper attachment that still suffices undemanding applications quite well. Establish the sheet’s thickness and gain since it relates to weight and strength; strength increases with thickness, but lighter sheets are easier to install. Determine the type of stainless steel finish, such as brushed or mirror stainless steel, to simplify cleaning or achieve the desired appearance. Moreover, determine the fabrication specifications; it should be easy to cut, weld, or mold into the shape one requires for the kitchen. Moreover, consider the location factors like humidity orthe presence of some corrosive liquids, determining the grade of corrosion resistance needed. Such measures would ensure that once invested in, the stainless steel will offer long term service and appearance for the kitchen.

Importance of Corrosion Resistance in Kitchen Appliances

Few things are more critical than the corrosion resistance of kitchen gadgets. Misplaced moisture, heat, or plenty of acids from food are only a few invalid conditions under which these gadgets constantly work. For me, the most appreciated feature is the stainless steel’s corrosion-resistance ability: for instance, grade 304 steel is both practical and gorgeous, being anti-aging to a whole new level. Leading resources indicate that, besides being cosmetically pleasing, it also withstands self-oxidization and rust, contributing to lower maintenance costs. This is especially important in appliances with heavy utilization, such as dishwashers or ovens, where maximum reliability is relished. Besides, the best stainless steel’s corrosion resistance adds to the hygienic performance of kitchen appliances due to the ease of maintenance and the low chance of bacteria being present. To conclude the sliding analysis, there is one apparent reason for choosing these materials: the outlook and the durability as they reinforce one another.

Factors to Consider: Thickness, Polish, and Finish

Regarding the thickness selection of stainless steel in the kitchen, my key parameters are strength and handling. I think the most reasonable is the 16 to 18-gauge (about 1.2 to 1.5 mm) thickness range. The thickness also makes the steel thinner than necessary while also imparting adequate strength to the steel. For polish, choosing a polish that is consistent with the aim and maintenance schedule is preferred. Like all others, an 8-mirror high polish finish is sleek looking, and as it means, it requires more cleaning.

On the other hand, a four brushed finish is suitable as it is elegant and easy to clean. Finishing touches include understanding relayed to omnidirectional polishing variations and surface finish specifications; in other words, the intensity of the eight mirror finish is likely to exceed 70% reflectivity, while brushed finishes possess random grains that counterfeit pavements. The help of the internet increases confidence in these parameters while at the same time helping one get the right balance between aesthetics and exterior.

Installation Tips for Stainless Steel Sheet in Kitchen

Stainless steel sheet installation in the kitchen should follow a well-thought-out strategy in execution and every single step in the preparation and installation, as failure will result in functional clutter. First of all, the location where the stainless steel will be fitted should be measured correctly along with the sheet so that it can fully cover the measurements. This will significantly limit the cutting and wastage of materials.

Finally, before the installation, take some time and ensure that the surface to be covered is clean. This means that it does not have any particles that would interfere with how well the adhesion will work. If adhesives are used, they should be suitable for joining metal surfaces. A good combination of high-speed and high-quality metal cutters/saws should be used when cutting so as to minimize ragged or rough burning and edges.

Fingerprints and smudges should be kept to a minimum when handling stainless steel, so take measures, such as wearing gloves, if you want to keep the metal in good condition. The other point to note during the saving process is the rust that results from screws, this can be avoided if non-colour fasteners like stainless screws are used since they are resisted to rusting thereby keeping the kitchen always neat. Also, placing insulating materials such as rubber and foam in between the sheet and the surface where it is placed will ensure that vibrations and noises are absorbed thereby increasing the practicality of the installation.

In the end, carry out multiple checks for alignment and proper placement of the sheet, ensuring it is properly placed on the kitchen’s existing surfaces so that there are no gaps or bulges. Utilizing these recommendations would also help achieve professional and aesthetic improvements in the kitchen’s design and practicality.

Frequently Asked Questions (FAQ)

Q: What is 304 stainless steel, and why is it famous for sheet metal?

A: 304 stainless steel is a grade within the 300 series known for its corrosion resistance, durability, and ease of maintenance. It is widespread and economical, wand it is idely used in various industries, including marine environments and food and beverage processing.

Q: What are the typical dimensions of a 4×8 stainless steel sheet?

A: A 4×8 stainless steel sheet typically measures 4 feet by 8 feet. This size is commonly used in construction and fabrication industries for its versatility and ease of handling.

Q: Can 304 stainless steel sheets be used in marine applications?

A: Yes, 304 stainless steel sheets are suitable for marine applications due to their resistance to corrosive environments. However, 316 stainless steel is often recommended for its enhanced corrosion resistance for more severe marine environments.

Q: How does 304 stainless steel compare to carbon steel?

A: 304 stainless steel offers superior corrosion resistance and is non-magnetic, unlike carbon steel, which is magnetic and more prone to rust. While carbon steel may be stronger, 304 stainless steel is preferred for applications where resistance to many corrosive substances is crucial.

Q: What finishes are available for 304 stainless steel sheets?

A: 304 stainless steel sheets come in various finishes, including 2b, four finish, bright annealed (ba), and satin. These finishes provide different levels of brightness and texture, suitable for a wide range of applications.

Q: Is 304 stainless steel heat treatable?

A: 304 stainless steel is not heat-treatable like carbon steel. However, it can be annealed to relieve stress and improve flexibility. This process involves heating and then slowly cooling the metal.

Q: What thicknesses are available for 4×8 stainless steel sheet metal?

A: 4×8 stainless steel sheet metal is available in various thicknesses, including 0.6mm, 20ga, 18ga, and 24ga. These options allow for flexibility depending on the project’s specific requirements.

Q: Can 304 stainless steel hold a magnet?

A: Generally, 304 stainless steel does not hold a magnet, as it is non-magnetic due to its chromium-nickel composition. However, slight magnetism can occur after cold working.

Q: What applications are ideal for 304 stainless steel sheets?

A: 304 stainless steel sheets are ideal for applications such as kitchen backsplashes, sinks, dairy and beverage equipment, and trim, thanks to their resistance to stains, durability, and attractive chrome finish.

Q: Do you offer cut-to-size services for stainless steel sheets?

A: Many suppliers offer cut-to-size services for stainless steel sheets, allowing customers to purchase stainless steel tailored to their specific project needs. For more information, it’s best to contact us for details.